Blue sky technology seems to be a perfect fit with the logistics industry – think robotics, self-driving vehicles and, of course, AI. But it’s often the smaller, less obvious ideas that make the biggest impact.

Take UPS, for example. In 2019, the US delivery company made headlines when it became a minority investor in autonomous-driving start-up TuSimple. Were we suddenly going to be seeing fleets of self-driving trucks delivering parcels up and down the US?

Not quite. The self-driving aspect of the business wasn’t all that UPS was interested in. ‘While fully autonomous, driverless vehicles still have development and regulatory work ahead, we’re excited by the advances in braking and other technologies that companies like TuSimple are mastering,’ UPS chief strategy and transformation officer Scott Price said at the time. ‘All of these technologies offer significant safety and other benefits that will be realised long before the full vision of autonomous vehicles is brought to fruition.’

The partnership has borne some fruit. While testing autonomous tractor-trailers in Arizona, TuSimple and UPS recorded significant fuel savings of 13%. Driverless freight trucks might be some time in coming, with TuSimple having since shifted its focus to China and other similar start-ups closing up shop. Bulgaria-based logistics start-up Transmetrics confirms this, saying in a July online post that while autonomous vehicles are one of the ‘most discussed logistics technology trends of recent time, we are still likely to see it in only its trial stage throughout the next year’.

In SA, where the logistics industry faces challenges on multiple fronts, not the least of which being security and crumbling infrastructure, the technology employed in the logistics industry might not be as flashy as autonomous driving, but it is making an impact.

Siyabonga Mthembu, audit partner at BDO South Africa, makes the point that the growth in e-commerce has been accompanied by a rise in demand for logistics services for quicker and more accurate movement of goods.

‘Any form of change in technology makes a huge difference. Technology these days drives the way we do business,’ he says. ‘With this said, it does not mean that to be a successful business, one must completely automate one’s business. Any form of change or implementation of technology goes a long way and has a significant impact on the business.’

He highlights trends such as the use of AI-driven chatbots to help real-time communication with customers, thus improving flow of information and ultimately logistics. ‘Any delays in information can be the difference between gaining or losing business. Therefore, AI-driven chatbots are one of the most useful and important applications in logistics.’

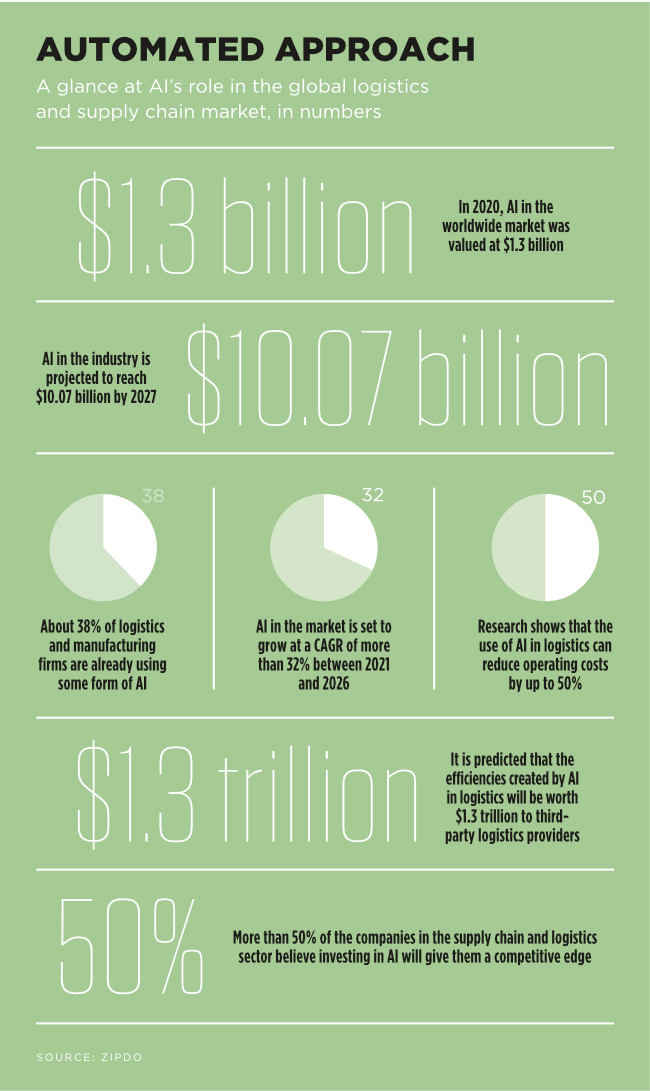

The role of AI – and the speed with which it can react to huge amounts of data – will become even more powerful in the future, according to MiX Telematics Africa fleet sales director Henry Smith. ‘Improved fleet safety is a huge benefit of vehicle tracking and fleet-management systems combined with AI technology,’ says Smith. ‘AI paired with dashcam tech, for example, can detect risky driving behaviour such as distracted driving, aggressive driving, texting, yawning and fatigue that may lead to accidents.’

Panellists at the 2023 SAPICS (South African Production and Inventory Control Society) conference agreed that AI could potentially improve supply chains and other business areas; they stressed, however, that organisations should not get distracted by the hype around AI.

Retief Gerber, CEO and co-founder of AI strategists Spatialedge, reported that in a project with the Western Cape government, AI had reduced road traffic fatalities by 30%. AI was used to predict where accidents were going to happen, assisting the traffic department to deploy their resources more effectively. While the project was a success, Gerber said AI was ‘nowhere near the singularity of Terminator’s Skynet’, referring to the block-buster movie in which a fictitious artificial general superintelligence system runs the world.

Farayi Kambarami, head of central planning and data at Woolworths, acknowledged that AI used in combination with automated robots was ‘improving pick accuracy in the distribution centres’. However, he wondered at the wisdom of using AI in these applications in SA, where there is a high degree of unemployment.

Panellists argued that businesses should first figure out what they want to achieve with the technology. Most importantly, since AI is only as good as the information it is fed, they stressed it is the quality of data that will give organisations the edge.

BDO’s Mthembu also cites total supply chain visibility as one of the technology trends to look out for. ‘This refers to the full view of the supply chain-management process, from procurement to product fulfilment and customer service. This allows the logistics service provider to give real-time feedback and updates on the shipments,’ he says.

By leveraging smart fleet-management systems, companies have reported significant improvements in their fleet’s overall efficiency. Reduced travel time, fuel consumption and maintenance costs result in substantial savings.

‘Something as simple as keeping up to date with maintenance schedules can be vital in extending the life cycle of vehicles, and doing so manually leaves too much room for error,’ says Justin Manson, sales director of Webfleet, a fleet-management provider that is a division of Bridgestone.

‘Not only does a commercial-grade telematics system provide regular reminders of upcoming scheduled maintenance for each vehicle, but it also monitors mechanical components in real time to flag any repairs that may need to be done, thus avoiding larger workshop bills down the line.’

Another benefit is journey management, based on roadworks or traffic jams. ‘Using vehicle tracking data not only helps optimise regular routes so that they use less fuel, but you can also ensure that they are more efficient and faster,’ says Smith.

‘You can reroute drivers when necessary to avoid slowdowns so that they arrive safely and on time. Journey management can also be used to improve a fleet’s utilisation. You can track and monitor drivers and vehicles, time spent in specific locations and routes taken to see if your resources are being over- or under-utilised. You can get insight into which assets and drivers and on which routes are contributing [negatively] to fuel consumption, maintenance costs and travel times. You can also see if delays are caused by traffic, lack of route knowledge or detours for unauthorised reasons,’ he says.

In warehousing, meanwhile, blockchain technology has been successful in combating cargo theft, while robotics has improved workforce safety.

‘The technologies are already demonstrating their potential,’ Amadou Diallo, CEO of DHL Global Forwarding for the Middle East and Africa, told the Africa Logistics website. ‘We will likely witness a shift from all-human facilities to collaborative human-machine facilities in the next few years.

‘In South Africa, for example, we are looking at introducing additional technologies that are being trialled in other warehouses abroad, including robots to help employees lift heavy cargo and wearable eyeglasses that help employees automatically scan parcel barcodes simply by looking at them.

‘In these future logistics warehouses, people and robots will work together to deliver speed and efficiency. These collaborative robots will be critical to improving worker safety, productivity and customer satisfaction. Machines won’t replace the human workforce but will complement them – especially in manual work and repetitive tasks. In turn, this is expected to make jobs safer and more focused on higher-value tasks. These roles are more attractive, encouraging more employees to join the workforce, which is a win-win for employers and employees.’

Older technologies are also being deployed in new ways to improve warehouse inventory control. Neil Gouveia, Africa director for Zebra Technologies, cites barcoding technology, which ‘has been around for decades, providing insight into the inventory across the supply chain, giving you visibility into what you have, but developments in tech allow us to do more. Take sensor technology – it makes it possible to have additional visibility in your normal or cold supply chains. So rather than having manual processes, wireless temperature sensors and colour-changing, temperature-sensing labels can automatically capture heat, freeze and shipment temperature data, providing you with the ability to see inventory conditions across the supply chain’.

Social media is not exactly an emerging technology, but according to Mthembu, it is ‘also becoming a powerful platform in optimising the logistics platform. Social media has become the most efficient way to communicate with customers, conveying urgent information and industry news, and customers are able to converse directly with the respective logistics companies’.