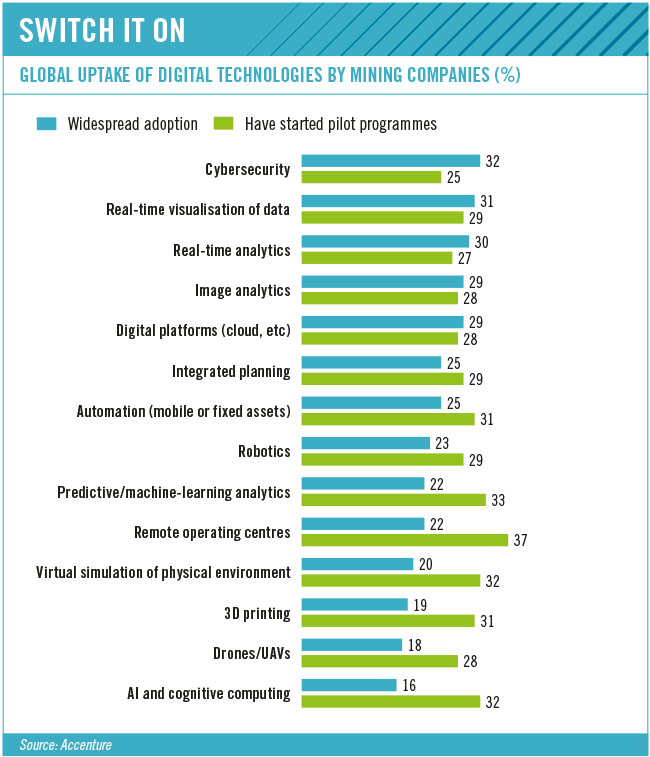

Anaemic global demand, massive excess capacity, weak pricing, and declining resource access and quality… The list of challenges facing global miners makes for gloomy reading. Yet as the industry comes to terms with what the WEF is calling the ‘new normal’, innovation driven by digital technology is emerging as a powerful solution to at least some of the problems.

In May – at the launch of Accenture’s Digital in Mining: Progress and Opportunity report, based on a worldwide survey of about 200 mining and metals executives and functional leaders – Rachael Bartels, the company’s global MD for chemicals and natural resources practice said: ‘Cost reduction is still on the agenda for miners, but focus is squarely on better-performing operations. Digital technologies enable operations to adjust to changing geology and market conditions, while still delivering returns.’

In the high-risk mining environment, safety is also a key component. Technology is crucial in reducing injuries and fatalities, according to Hannes Potgieter, marketing director of Battery Electric, which designs and manufactures microprocessor controllers that can be integrated with vehicle management and other control systems. ‘From the automation of equipment and implementation of robotics to monitoring operator behaviour, technology enables miners to be proactive – not reactive.’

Accenture’s report highlighted how – when asked about the overall business benefits of using digital technologies across the organisation – executives most often cited improved workforce productivity automation, visualisation and the ability to simulate physical environments. According to Accenture: ‘That’s not surprising because productivity is an area with considerable room for improvement in the industry – and it is fairly easy to identify the productivity improvements from digital technology.’

In line with this, the report showed mining firms to be especially interested in getting ‘the right data in the right time frame to help people take the right actions and react quickly to changing situations’, enabled by technologies such as robotics/automation, drones, remote operating centres and wearable technology.

‘Together, those technologies paint a coherent picture in which miners are developing more timely operational data through digital visibility, automated processes and drones; using remote operating centres to make collaborative decisions with that data; and using wearables to share data with individuals,’ according to the report.

Schneider Electric’s EcoStruxure platform for mining, minerals and metals provides exactly this – leveraging digital technologies and the industrial internet of things to enable firms to seamlessly connect, collect, analyse and act on data in real time to improve safety, efficiency, reliability and sustainability.

‘The mining, cement, steel and glass industries face constant challenges that place a premium on operational excellence,’ says Wilhelm Swart, Schneider Electric mining, minerals and metals Africa business vice-president. ‘There has been significant transformation in digital technologies that are available to help with many of these challenges. By leveraging this, EcoStruxure helps our customers improve how they manage their operations and plants to improve the bottom line.’

As data forms the basis of any smart solution that will deliver cost savings, improve efficiency and productivity or generate more revenue, says Barry Elliott, MD of Rockwell Automation South Africa.

‘Selecting a specific operational area, then analysing that area using a combination of the live and historical plant operating data already available, and then applying analytics to this data can rapidly derive tangible benefits,’ he says.

Gys Kappers, CEO of software firm Wyzetalk, argues that innovation can – and should – drive more than just cost reduction. ‘It can help mitigate and manage risk, strengthen business models and foster more effective relations,’ he says. ‘Mining companies need to prepare to shift traditional entrenched models, plan for future scenarios where collaboration is at the centre of a lean operation, and use digitalisation to drive the industry forward.

‘By its very nature, mining presents a range of health and safety issues, from ground instability to the presence of hazardous materials, heavy-duty machinery and processes that aren’t always synchronised – creating points of failure in the gaps. Deepening mines are also presenting new challenges to health and safety, and the recent fatalities that have occurred in South African mines have us also questioning the systems we have in place to read and assess geological factors and early-warning detectors, along with our evacuation strategies.’

The question then is what can companies do to reduce injuries and fatalities underground? ‘The short answer is a new model of operating,’ says Kappers. ‘One that moves away from siloed departmental functioning, and one that is supported by a far more dynamic and proactive communications system that puts employees at the centre.’

Axis Communications country manager Roy Alves, has a similar take and points out that SA mines are now able to improve their safety and security by using the latest network video intelligent surveillance. ‘The last few months have seen better performance at lower prices, making effective and efficient intelligent surveillance much more readily accessible,’ says Alves. ‘Cameras are becoming more efficient – they’re now able to monitor remotely in lieu of needing an on-site presence, particularly in the case of non-working mines. With lower bandwidth costs, it is now possible to monitor remotely, pulling feed across to a central monitoring station.’

Examples of improved camera technology include explosion-protected cameras encased in stainless steel housings; electronic image stabilisation and light finder technology – which automatically adapts from sunlight to darkness, providing detail across both dark and bright areas simultaneously.

Another example is the recent introduction of thermal cameras, capable of detecting heat signatures above a predetermined temperature threshold. These cameras could, for instance, detect any heat above 40°C and send an alarm to a centralised control room. ‘Prevention is always better than cure,’ say Alves. ‘It’s about business intelligence. Mines, as far as possible, need to be notified before an event occurs, rather than two hours too late.’

Discussions on the impact of digital technology on the mining industry tend to focus on attention-grabbing gadgets such as automated vehicles or unmanned drones, or on hot topics such as artificial intelligence and big data. The reality on, under and high above the ground shows that mine bosses are actually more focused on smart solutions that can immediately reduce costs and improve efficiencies. This is not limited to underground operations alone. A new training project piloted by ArcelorMittal demonstrates how digital technology can help mining firms at other levels of the organisation.

ArcelorMittal is currently training its crane workers using a virtual reality (VR) app, developed by tech company Sea Monster on behalf of consultancy LRMG. ‘The issue was part training, part safety,’ says Glenn Gillis, Sea Monster’s MD.

‘Under normal conditions you can’t have your trainees working at heights until they’ve been through the training course. But the problem there is that ArcelorMittal would take its candidates through that course, only to then find – when those trainees had their first real-life experience of working at heights – that about 40% of them are afraid of heights. In this case, the trainee would either freeze or be too frazzled to work effectively, and this would endanger their lives and the lives of their co-workers.’

Sea Monster’s VR solution simulates working at heights. ‘We have them perform a few tasks while we monitor their heart rates and the accuracy with which they perform them. The system then outputs a score, which ArcelorMittal can use to determine whether or not to hire those candidates for working at heights,’ says Gillis.

That said, technologies that improve safety levels while saving costs and boosting efficiencies aren’t limited to VR, automation and the like. Workplace safety requires a multifaceted approach, and in this mix, clearly visible signage is crucial in helping employees negotiate high-risk working environments where extremely wet or dusty conditions generally apply.

‘Paint might not be the first thing that comes to mind in a high-tech mining discussion, but safety compliance – and hence sustainable mining – depends on paying due attention to the details,’ says Rolf Redelinghuys, Kansai Plascon’s Africa market manager of mines and roadmarkings. The company has developed a new enamel paint specifically for the mining industry – it renders safety signs more effective in an underground environment.

As the Accenture report notes: ‘Technology is the enabler, but achieving real value depends on how businesses leverage the technology. If companies are satisfied with the value they are seeing from their investments, it boosts buy-in and interest – and that can help drive success and sustained results from the growing use of digital technology.’