The impact of concrete and how it improves lives – be it environmental or social – consumes PPC, and has done so since its inception 130 years ago. This encompasses the contribution it has made to iconic SA constructs such as the Union Buildings, Van Stadens Bridge, the 2010 World Cup stadiums and innumerable schools, hospitals and homes.

‘There are a lot of lives that PPC has touched over these decades,’ says Njombo Lekula, PPC MD of Southern Africa. ‘It’s not for nothing that we say “people are our strength” – be that our employees who carry the brand and the aspirations of our business, our customers and communities in which we operate, and our shareholders, to whom we have paid valuable dividends over the years.’

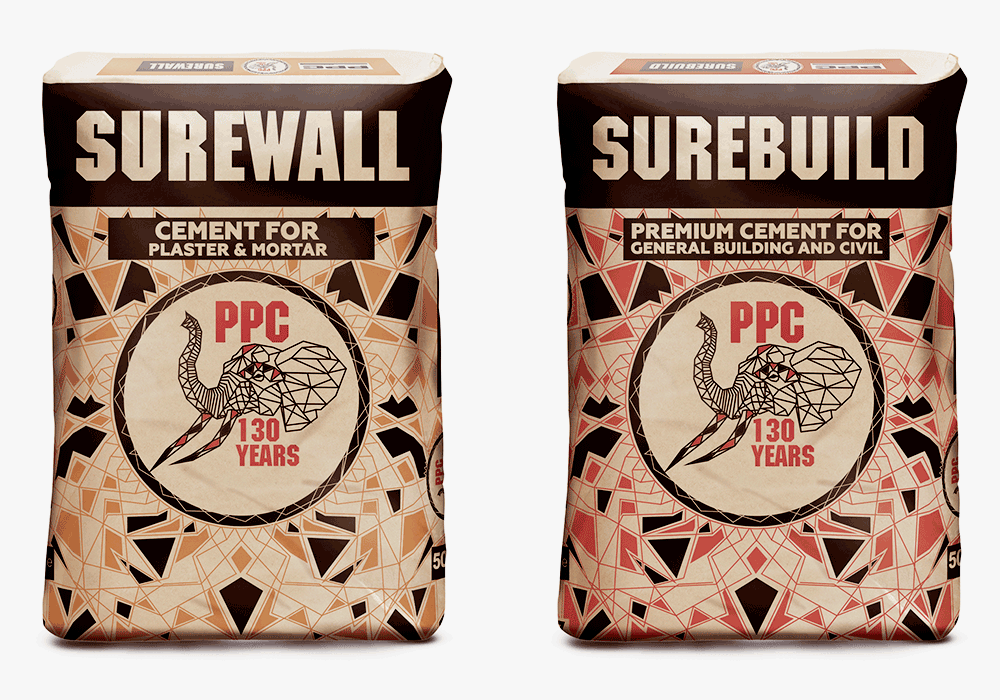

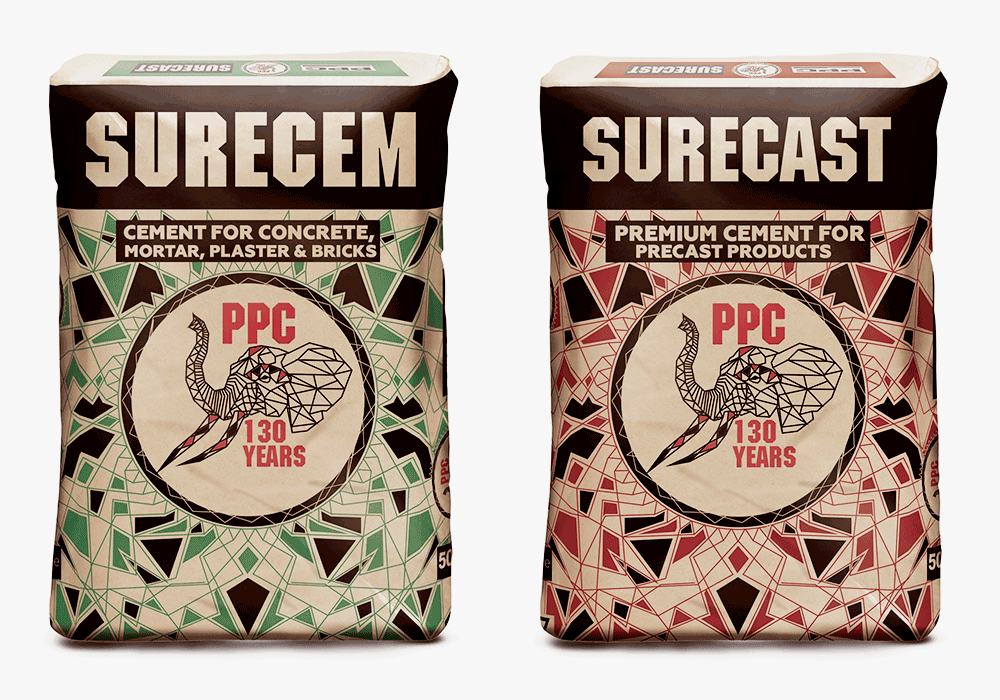

That value has been generated by PPC’s expansion into Africa, and diversification into building materials and solutions. The innovation of its Sure range has also played a role, given it is a fit-for-purpose product, as have PPC’s ready-mix aggregates, fly ash and water-based pre-mix products.

While the company sustains its identity of being a leading and innovative producer of cement, PPC has invested a substantial amount in transforming the industry, encouraging and training new blood to enter the sector, and motivating government to make positive changes that discourage imports in favour of increased local production, which has the added benefit of addressing job creation.

‘South Africa consumes some 14 million tons of cement,’ says Lekula. ‘Yet, despite the capacity to produce 19 million tons, there is a deficit that is picked up by imports of some 1.4 million. This is counterproductive, especially if you consider that 1.4 million tons is equivalent to one factory, which could be directly employing some 400 to 500 local people.’

This issue, which PPC has taken up with government, places emphasis on the fact that the cement industry currently contributes – through direct and indirect jobs – employment for 1.3 million people.

‘The value that the sector generates is significant, and can be increased. We are doing what we can to encourage the government and the sector to improve the situation for all,’ says Lekula.

‘Shared value’ is the concept that PPC embraces. Over the past decade it has focused on empowering customers and consumers with knowledge about the use of its products. It has further provided training to more than 4 000 brick-makers, concentrating on the youth who take part in PPC’s accredited plastering and construction management courses. About 200 youth have acquired such skills over the past seven months alone.

Very close to Lekula’s heart is the PPC Technical Services Academy, which extends electrical, boiler-making and mechanical skills acquisition, and which is equally popular with young males and females.

Youth yet again are a focus in PPC’s YES programme, which provides work experience to unemployed graduates. According to Lekula, ‘121 youth have been through this programme, gaining invaluable experience and jobs’.

Then there’s the PPC enterprise-development programme, which focuses on business incubation and access to markets for local businesses and entrepreneurs.

‘A key part of our business is logistics, and this also allows us to create value for outsourcing to entrepreneurs. We have developed a number of entrepreneurs in the communities in which we operate ensuring that those are included in the ecosystem of the business,’ says Lekula. ‘We have a number of SMEs, for example, that service PPC with its personal-protection equipment requirements, such as overalls and masks.

‘I believe that in being a corporate elder and leader in the industry, there is an imperative to similarly lead and guide others, and not for compliance sake,’ says Lekula. ‘We believe that if we empower people it makes us all more sustainable, as businesses and communities.

This, however, involves more than just job creation, excellence in product delivery and quality, he says. Lekula is promoting just how significant cement is to the sustainability of life, which impacts on how PPC continues to manufacture product and the impact that the organisation has on the environment.

‘We recently launched our decarbonisation strategy that will be achieved by 2030,’ he says. ‘This involves innovation in product development and includes the use of solar energy and alternative sources of fuel at our plants.’

One of those fuel alternatives is tyres, which PPC is already using at its De Hoek plant in Piketburg, which was built in 1932 and is considered one of the oldest plants in SA. The kiln using recycled tyres is projected to have a co-processing capacity of some 8 000 tons of recycled tyres annually, replacing traditional thermal heat by some 10%, and dramatically reducing the impact of carbon taxes on PPC, from R150 million to R120 million.

PPC’s environmental programmes have also seen good water-management initiatives that have decreased water consumption at the De Hoek and Riebeeck plants.

Mine-water recycling contributed to an average potable water savings of up to 19% and 40% in 2019 and 2020 respectively. Rainwater harvesting and raw mill cooler reticulation systems are also used as part of the water-management strategy.

‘Being a responsible corporate citizen means we are dedicated to playing an active role in protecting and preserving the environment by addressing climate change, preventing pollution, encouraging the sustainable use of resources and protecting ecosystems,’ says Lekula.

‘These are integrated into our true purpose, which is to empower people to experience a better quality of life in the same way that we have done. PPC looks forward to another 130 years of existence of motivating change.’